Hello,

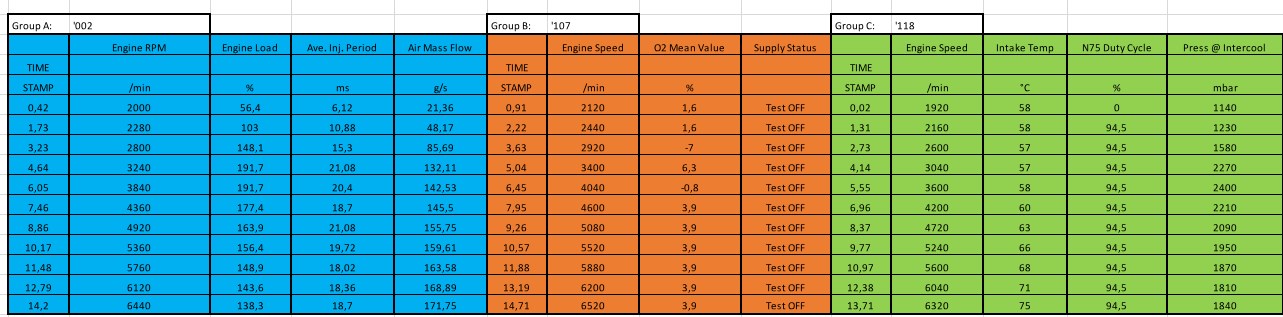

I have got a remap from Uber UK and I can feel that there is no big change so far, here is some data:

![Image]()

The N75 is always at 95% after 2k RPM, the MAF indicates 180 g/s max on my runs, hence 225 HP (180/0.8).

Do you see any clue in these data ?

Thanks for your help,

Katak

I have got a remap from Uber UK and I can feel that there is no big change so far, here is some data:

The N75 is always at 95% after 2k RPM, the MAF indicates 180 g/s max on my runs, hence 225 HP (180/0.8).

Do you see any clue in these data ?

Thanks for your help,

Katak