Yeah, basically once a fault is detected, the switch and automatic operation is disabled. This is pretty common when people make the mistake of opening the top while moving or if they attempt to open the top without the engine running and a low voltage fault occurs. Fortunately, it's often a simple fix by opening and closing the top manually with the ignition turned to the first position.

Having said that, if there's a problem with the roof flap servo motor, the top is definitely out of service and will have to be corrected by a shop. But you can try the ignition turned to first position (accessory) and see if opening/closing the top solves the problem.

So the top is closed, but the spline shaft won't come out? Ah, the joys of Roadster tops!! :lol:

First, I'll be honest, I'm not sure what that bracket is for. Would it be possible to get a few more pictures, maybe a bit farther away from the motor and a couple of different side shots would be helpful. As you can see in my photos, I don't have that feature in mine so I don't know if this is something unique your year.

As you correctly noted, the crank arm tool stud is broken off inside the spline shaft. You can see the little silver piece of it where indicated inside the spline shaft. You don't have to replace the spline shaft or the crank arm as long as you can pull the spline out. But if you do, be sure to get a new crank arm. Or, leave the spline shaft as is and toss a pair of Vise Grip pliers in the trunk. They'll come in handy in an emergency if the window regulator craps out.

Unfortunately this is a very common problem no thanks to Audi's less than intuitive design, poor instructions in the owners manual and a lack of understanding by owners as to what's involved.

But anyway. Back to your situation -

If the channel locks didn't work, try to pull it out using Vise grips. They will provide a better grip than channel locks. That end of the spline shaft doesn't matter so if you bung it up a bit in the attempt, it's not an issue.

If that fails to do the trick, what can happen is there's pressure on the spline shaft from the motor spline and upper latch spline as the way the motors is mounted. Basically the top and bottom of the spline shaft are being pushed in opposite directions making removal a challenge.

But give it your best attempt with the Vise grips first. don't worry about clamping down too hard on the spline shaft, it's hardened steel.

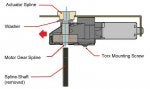

If you still can't get it out with Vise Grips, what may help is to unscrew the Torx motor mount screw to loosen the motor. You don't need to unscrew it completely, just a couple of turns so it's loose. If the spline shaft still refuses to come out, then go ahead and remove the screw as removing the entire motor is the next step. There's a long double-ended torx in the tool kit which will fit into the screwdriver handle. Here's a couple more posts on the issue -

https://www.ttforum.co.uk/forum/viewtop ... 2&start=75 (Page 6)

https://www.ttforum.co.uk/forum/viewtop ... &t=1827978

Whatever you do, don't attempt to turn the spline shaft while it's inside the motor or you will severely damage the motor. The point of removing the spline shaft is so you can get the spline end of the crank arm tool through and past the motor spline, so you can engage the latch spline.

So when you get a good grip on it with the Vise Grips, just pull straight out.

Don't attempt to turn or rotate it. I've included this illustration to show how, once the spline shaft is removed, the crank arm tool engages with the latch spline.

I'll keep an eye on this post today, so let me know how this works out. [smiley=thumbsup.gif]