Had a similar issue with a non functioning spoiler that had plagued the car for a long time. I thought I had previously fixed it as it was showing this code in

03132 - Limit Switch for Rear Spoiler Movement (F135/F136)

008 - Implausible Signal - Intermittent

Connecting 12v directly to the motor and running it in a full cycle fixed it or so I thought. However it came back again a few months later and would not operate. Found the awesome post by Swissjetpilot, thank you!, and found a solution after doing a lot of diagnosis.The spoiler was nicely lubricated and moved easily, worked perfectly with a direct 12v 1.5a supply from a transformer, I was not keen on rigging it directly to the battery as that is a big load. The microswitches worked fine, tested ok throughout the loom down to the CCM (2009 with a seperate unit). The CCM showed no signs of corrosion or dry joints when opened fully and showed no other codes so looked good.I checked the loomfrom CCM to the central connector on the boot lid where the wiring splits to the motor and the microswitches and this was fine too. All plugs and pins were fine.

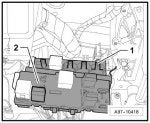

The issue was the loom from the central connector Under the boot lid to the motor itself. Putting the above supply into these pins would not operate the motor. The loom here is only maybe 15cm, on further investigation I opened up the Heatshrink on it to find two large resistors running from the positive to negative wires. I’ve only ever seen or used resistors on a positive wire, never jump wrong between a positive and negative wires. Beyond my knowledge of electrickery as to why this had been done, my only thought was to reduce the load on the motor possibly somehow??as This was my fault location as far as I could see, so I tried bypassing the negative wire from one plug to another, and after clearing the codes, it works and at perfect speed. I’m unsure of whether one resistor ( they are wired in parallel) has failed, or what is going on here, maybe someone can test the resistance of this loom? I think mine was showing 0.3 ohm but I forgot the scale of ohms the multimeter was on so may be kiloohms etc. I am unsure and after hours on it not keen to rip it apart!

This fix worked for me, and can hopefully help someone else, it may be just this loom is causing issues to save someone installing a whole new mechanism. I used a red jumper wire in the picture below, soldered it onto each end of the loom near the plugs to bypass the resistors, it may be an easy test for someone investigating issues by just pushing a wire into the back of both ends of the negative wire in each plug. No need to cut off the Heatshrink and re-seal it after like I did. But comparing resistance values on this loom with both ends unplugged should shed some light on whether these resistors have failed or not. I just didn’t want to cut them from the loom to test them individually. Also in hindsight I should’ve soldered my repair wire to either end of the light blue wire, and not across the plug to the black wire with blue trace as the was no issue at the plug. Also probably use a more suitable colour of wire like black or brown as it was a negative wire. I was just stupid and too excited to fix it!

![Image]()